API casing pipe is produced according to the API 5CT standard. It is most often used in underground construction projects to encase or protect utility lines from being damaged.

It is widely used in the cementing projects to serve as the structural retainer for the wall of oil and gas wells or wellbore. It is inserted into a well bore and cemented in place to protect both subsurface formations and the wellbore from collapsing and allow drilling fluid to circulate and extraction to take place.

Specification:

Material: H40, J55, K55, N80-1, N80-Q, M65, L80-1, C90-1, T95, P110, Q125, etc.

Outer diameter: 4-1/2" to 20".

WT: 5.21 mm to 16.13 mm (9.5 PPF to 133PPF)

Standard: API 5CT.

Thread connection: STC, LTC, BTC, XC and Premium connection

Length: R1, R2, R3

Popular Specifications of Sucker API Casing Pipe | ||||||||||||

Sizes | OD (mm) | Weight (kg/m) | WT (mm) | Type of End | ||||||||

H40 | J55/K55 | M65 | L80/C95 | N80-1/N80-Q | C90/T95 | P110 | Q125 | |||||

1 | 2 | |||||||||||

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

4-1/2 | 9.5 | 114.3 | 14.14 | 5.21 | PS | PS | PS | – | – | – | – | – |

4-1/2 | 10.5 | 114.3 | 15.63 | 5.69 | – | PSB | PSB | – | – | – | – | – |

4-1/2 | 11.6 | 114.3 | 17.26 | 6.35 | – | PSLB | PLB | PLB | PLB | PLB | PLB | – |

4-1/2 | 13.5 | 114.3 | 20.09 | 7.37 | – | – | PLB | PLB | PLB | PLB | PLB | – |

4-1/2 | 15.1 | 114.3 | 22.47 | 8.56 | – | – | – | – | – | – | PLB | PLB |

5 | 11.5 | 127 | 17.11 | 5.59 | – | PS | PS | – | – | – | – | – |

5 | 13 | 127 | 19.35 | 6.43 | – | PSLB | PSLB | – | – | – | – | – |

5 | 15 | 127 | 22.32 | 7.52 | – | PSLBE | PLB | PLBE | PLBE | PLBE | PLBE | – |

5 | 18 | 127 | 26.79 | 9.19 | – | – | PLB | PLBE | PLBE | PLBE | PLBE | PLBE |

5 | 21.4 | 127 | 31.85 | 11.1 | – | – | PLB | PLB | PLB | PLB | PLB | PLB |

5 | 23.2 | 127 | 34.53 | 12.14 | – | – | – | PLB | PLB | PLB | PLB | PLB |

5 | 24.1 | 127 | 35.86 | 12.7 | – | – | – | PLB | PLB | PLB | PLB | PLB |

5-1/2 | 14 | 139.7 | 20.83 | 6.2 | PS | PS | PS | – | – | – | – | – |

5-1/2 | 15.5 | 139.7 | 23.07 | 6.98 | – | PSLBE | PSLB | – | – | – | – | – |

5-1/2 | 17 | 139.7 | 25.3 | 7.72 | – | PSLBE | PLB | PLBE | PLBE | PLBE | PLBE | – |

5-1/2 | 20 | 139.7 | 29.76 | 9.17 | – | – | PLB | PLBE | PLBE | PLBE | PLBE | – |

5-1/2 | 23 | 139.7 | 34.23 | 10.54 | – | – | PLB | PLBE | PLBE | PLBE | PLBE | PLBE |

5-1/2 | 26.8 | 139.7 | 39.88 | 12.7 | – | – | – | – | – | P | – | – |

5-1/2 | 29.7 | 139.7 | 44.2 | 14.27 | – | – | – | – | – | P | – | – |

5-1/2 | 32.6 | 139.7 | 48.51 | 15.88 | – | – | – | – | – | P | – | – |

5-1/2 | 35.3 | 139.7 | 52.53 | 17.45 | – | – | – | – | – | P | – | – |

5-1/2 | 38 | 139.7 | 56.55 | 19.05 | – | – | – | – | – | P | – | – |

5-1/2 | 40.5 | 139.7 | 60.27 | 20.62 | – | – | – | – | – | P | – | – |

5-1/2 | 43.1 | 139.7 | 64.14 | 22.22 | – | – | – | – | – | P | – | – |

6-5/8 | 20 | 168.28 | 29.76 | 7.32 | PS | PSLB | PSLB | – | – | – | – | – |

6-5/8 | 24 | 168.28 | 35.72 | 8.94 | – | PSLBE | PLB | PLBE | PLBE | PLBE | PLBE | – |

6-5/8 | 28 | 168.28 | 41.67 | 10.59 | – | – | PLB | PLBE | PLBE | PLBE | PLBE | – |

6-5/8 | 32 | 168.28 | 47.62 | 12.06 | – | – | – | PLBE | PLBE | PLBE | PLBE | PLBE |

7 | 17 | 177.8 | 25.3 | 5.87 | PS | – | – | – | – | – | – | – |

7 | 20 | 177.8 | 29.76 | 6.91 | PS | PS | PS | – | – | – | – | – |

7 | 23 | 177.8 | 34.23 | 8.05 | – | PSLBE | PLB | PLBE | PLBE | PLBE | – | – |

7 | 26 | 177.8 | 38.69 | 9.19 | – | PSLBE | PLB | PLBE | PLBE | PLBE | PLBE | – |

7 | 29 | 177.8 | 43.16 | 10.36 | – | – | PLB | PLBE | PLBE | PLBE | PLBE | – |

7 | 32 | 177.8 | 47.62 | 11.51 | – | – | PLB | PLBE | PLBE | PLBE | PLBE | – |

7 | 35 | 177.8 | 52.09 | 12.65 | – | – | – | PLBE | PLBE | PLBE | PLBE | PLBE |

7 | 38 | 177.8 | 56.55 | 13.72 | – | – | – | PLBE | PLBE | PLBE | PLBE | PLBE |

7 | 42.7 | 177.8 | 63.54 | 15.88 | – | – | – | – | – | P | – | – |

7 | 46.4 | 177.8 | 69.05 | 17.45 | – | – | – | – | – | P | – | – |

7 | 50.1 | 177.8 | 74.56 | 19.05 | – | – | – | – | – | P | – | – |

7 | 53.6 | 177.8 | 79.77 | 20.62 | – | – | – | – | – | P | – | – |

7 | 57.1 | 177.8 | 84.97 | 22.22 | – | – | – | – | – | P | – | – |

7-5/8 | 24 | 193.68 | 35.72 | 7.62 | PS | – | – | – | – | – | – | – |

7-5/8 | 26.4 | 193.68 | 39.29 | 8.33 | – | PSLBE | PSLB | PLBE | PLBE | PLBE | – | – |

7-5/8 | 29.7 | 193.68 | 44.2 | 9.52 | – | – | PLB | PLBE | PLBE | PLBE | PLBE | – |

7-5/8 | 33.7 | 193.68 | 50.15 | 10.92 | – | – | PLB | PLBE | PLBE | PLBE | PLBE | – |

7-5/8 | 39 | 193.68 | 58.04 | 12.7 | – | – | – | PLBE | PLBE | PLBE | PLBE | PLBE |

7-5/8 | 42.8 | 193.68 | 63.69 | 14.27 | – | – | – | PLB | PLB | PLB | PLB | PLB |

7-5/8 | 45.3 | 193.68 | 67.41 | 15.11 | – | – | – | PLB | PLB | PLB | PLB | PLB |

7-5/8 | 47.1 | 193.68 | 70.09 | 15.88 | – | – | – | PLB | PLB | PLB | PLB | PLB |

7-5/8 | 51.2 | 193.68 | 76.19 | 17.45 | – | – | – | – | – | P | – | – |

7-5/8 | 55.3 | 193.68 | 82.3 | 19.05 | – | – | – | – | – | P | – | – |

7-3/4 | 46.1 | 196.85 | 68.6 | 15.11 | – | – | – | P | P | P | P | P |

8-5/8 | 24 | 219.08 | 35.72 | 6.71 | – | PS | PS | – | – | – | – | – |

8-5/8 | 28 | 219.08 | 41.67 | 7.72 | PS | – | PS | – | – | – | – | – |

8-5/8 | 32 | 219.08 | 47.62 | 8.94 | PS | PSLBE | PSLB | – | – | – | – | – |

8-5/8 | 36 | 219.08 | 53.57 | 10.16 | – | PSLBE | PSLB | PLBE | PLBE | PLBE | – | – |

8-5/8 | 40 | 219.08 | 59.53 | 11.43 | – | – | PLB | PLBE | PLBE | PLBE | PLBE | – |

8-5/8 | 44 | 219.08 | 65.48 | 12.7 | – | – | – | PLBE | PLBE | PLBE | PLBE | PLBE |

8-5/8 | 49 | 219.08 | 72.92 | 14.15 | – | – | – | PLBE | PLBE | PLBE | PLBE | |

9-5/8 | 32.3 | 244.48 | 48.07 | 7.92 | PS | – | – | – | – | – | – | – |

9-5/8 | 36 | 244.48 | 53.57 | 8.94 | PS | PSLB | PSLB | – | – | – | – | – |

9-5/8 | 40 | 244.48 | 59.53 | 10.03 | – | PSLBE | PSLB | PLBE | PLBE | PLBE | – | – |

9-5/8 | 43.5 | 244.48 | 64.73 | 11.05 | – | – | PLB | PLBE | PLBE | PLBE | PLBE | – |

9-5/8 | 47 | 244.48 | 69.94 | 11.99 | – | – | PLB | PLBE | PLBE | PLBE | PLBE | PLBE |

9-5/8 | 53.5 | 244.48 | 79.62 | 13.84 | – | – | – | PLBE | PLBE | PLBE | PLBE | PLBE |

9-5/8 | 58.4 | 244.48 | 86.91 | 15.11 | – | – | – | PLB | PLB | PLB | PLB | PLB |

9-5/8 | 59.4 | 244.48 | 88.4 | 15.47 | – | – | – | – | – | P | – | – |

9-5/8 | 64.9 | 244.48 | 96.58 | 17.07 | – | – | – | – | – | P | – | – |

9-5/8 | 70.3 | 244.48 | 104.62 | 18.64 | – | – | – | – | – | P | – | – |

9-5/8 | 75.6 | 244.48 | 112.5 | 20.24 | – | – | – | – | – | P | – | – |

10-3/4 | 32.75 | 273.05 | 48.74 | 7.09 | PS | – | – | – | – | – | – | – |

10-3/4 | 40.5 | 273.05 | 60.27 | 8.89 | PS | PSB | PSB | – | – | – | – | – |

10-3/4 | 45.5 | 273.05 | 67.71 | 10.16 | – | PSBE | PSB | – | – | – | – | – |

10-3/4 | 51 | 273.05 | 75.9 | 11.43 | – | PSBE | PSB | PSBE | PSBE | PSBE | PSBE | – |

10-3/4 | 55.5 | 273.05 | 82.59 | 12.57 | – | – | PSB | PSBE | PSBE | PSBE | PSBE | – |

10-3/4 | 60.7 | 273.05 | 90.33 | 13.84 | – | – | – | – | – | PSBE | PSBE | PSBE |

10-3/4 | 65.7 | 273.05 | 97.77 | 15.11 | – | – | – | – | – | PSB | PSB | PSB |

10-3/4 | 73.2 | 273.05 | 108.93 | 17.07 | – | – | – | – | – | P | – | – |

10-3/4 | 79.2 | 273.05 | 117.86 | 18.64 | – | – | – | – | – | P | – | – |

10-3/4 | 85.3 | 273.05 | 126.94 | 20.24 | – | – | – | – | – | P | – | – |

11-3/4 | 42 | 298.45 | 62.5 | 8.46 | PS | – | – | – | – | – | – | – |

11-3/4 | 47 | 298.45 | 69.94 | 9.53 | – | PSB | PSB | – | – | – | – | – |

11-3/4 | 54 | 298.45 | 80.36 | 11.05 | – | PSB | PSB | – | – | – | – | – |

11-3/4 | 60 | 298.45 | 89.29 | 12.42 | – | PSB | PSB | PSB | PSB | PSB | PSB | PSB |

11-3/4 | 65 | 298.45 | 96.73 | 13.56 | – | – | – | P | P | P | P | P |

11-3/4 | 71 | 298.45 | 105.66 | 14.78 | – | – | – | P | P | P | P | P |

13-3/8 | 48 | 339.72 | 71.43 | 8.38 | PS | – | – | – | – | – | – | – |

13-3/8 | 54.5 | 339.72 | 81.1 | 9.65 | – | PSB | PSB | – | – | – | – | – |

13-3/8 | 61 | 339.72 | 90.78 | 10.92 | – | PSB | PSB | – | – | – | – | – |

13-3/8 | 68 | 339.72 | 101.19 | 12.19 | – | PSB | PSB | PSB | PSB | PSB | PSB | – |

13-3/8 | 72 | 339.72 | 107.15 | 13.06 | – | – | – | PSB | PSB | PSB | PSB | PSB |

16 | 65 | 406.4 | 96.73 | 9.53 | PS | – | – | – | – | – | – | – |

16 | 75 | 406.4 | 111.61 | 11.13 | – | PSB | PSB | – | – | – | – | – |

16 | 84 | 406.4 | 125.01 | 12.57 | – | PSB | PSB | – | – | – | – | – |

16 | 109 | 406.4 | 162.21 | 16.66 | – | P | – | P | P | – | P | P |

18-5/8 | 87.5 | 473.08 | 130.21 | 11.05 | PS | PSB | PSB | – | – | – | – | – |

20 | 94 | 508 | 139.89 | 11.13 | PSL | PSLB | PSLB | – | – | – | – | – |

20 | 106.5 | 508 | 158.49 | 12.7 | – | PSLB | PSLB | – | – | – | – | – |

20 | 133 | 508 | 197.93 | 16.13 | – | PSLB | – | – | – | – | – | – |

API 5CT Casing Pipe Physical Strength

Group | Grade | Type | Total elongation under load % | Yield strength MPa | Tensile strength min. MPa | Hardness a max. | Specified wall thickness mm | Allowable hardness variation b HRC | ||

min | max | HRC | HBW | |||||||

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

1 | H40 | – | 0.5 | 276 | 552 | 414 | – | – | – | – |

J55 | – | 0.5 | 379 | 552 | 517 | – | – | – | – | |

K55 | – | 0.5 | 379 | 552 | 655 | – | – | – | – | |

N80 | 1 | 0.5 | 552 | 758 | 689 | – | – | – | – | |

N80 | Q | 0.5 | 552 | 758 | 689 | – | – | – | – | |

R95 | – | 0.5 | 655 | 758 | 724 | – | – | – | – | |

2 | M65 | – | 0.5 | 448 | 586 | 586 | 22 | 235 | – | – |

L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 | – | – | |

L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | – | – | |

L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | – | – | |

C90 | 1 | 0.5 | 621 | 724 | 689 | 25.4 | 255 | ≤ 12.70 12.71 to 19.04 19.05 to 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

T95 | 1 | 0.5 | 655 | 758 | 724 | 25.4 | 255 | ≤ 12.70 12.71 to 19.04 19.05 to 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

C110 | – | 0.7 | 758 | 828 | 793 | 30 | 286 | ≤ 12.70 12.71 to 19.0 19.05 to 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

3 | P110 | – | 0.6 | 758 | 965 | 862 | – | – | – | – |

4 | Q125 | 1 | 0.65 | 862 | 1034 | 931 | b | – | ≤ 12.70 12.71 to 19.04 ≥ 19.05 | 3.0 4.0 5.0 |

a In case of dispute, laboratory Rockwell C hardness testing shall be used as the referee method. | ||||||||||

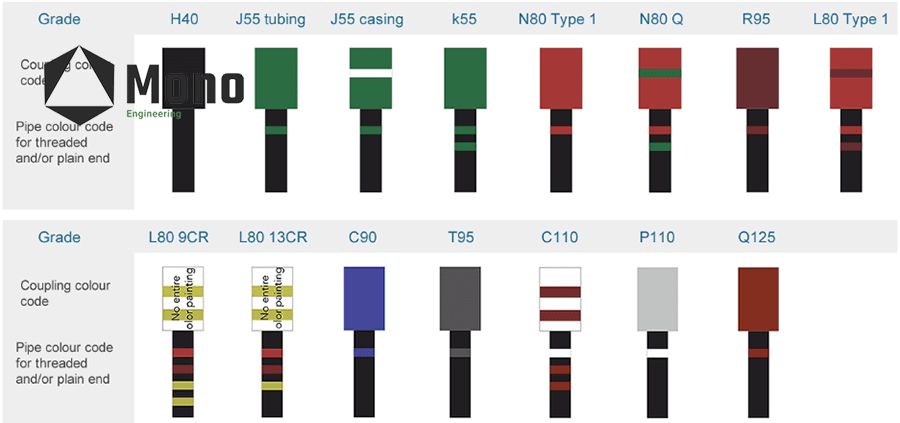

API 5CT Casing Pipe Coupling colors:

API 5CT Casing Pipe Coupling colors: