Introduction:

Tubing basically means a tube running inside casing and serves as a channel through which oil and gas is produced. It must be adequately strong enough to resist loads and deformations associated with production and workovers. It should also be sized to support the expected rates of production of oil and gas. If the tube is too small, it would restrict production and subsequent economic performance of the well. If too large, however, it will have an economic impact beyond the cost of the tubing string itself, because the tubing size will influence the overall casing design of the well.

Specification :

Standard and Grades: API 5CT J55 / K55, N80-1, N80Q, C90, T95, P110, Q125 and 13Cr

Tubing Pipe dimensions range: 1.0”, 1.315”, 1.66”, 1.9”, 2.063 ”, 2 3/8”, 3 1/2”,4 1 /2”

Length: R1, R2, R3

Connection: EU, NU, IJ, Premium Connection (VAM TOP, NEW VAM, PH-6)

API 5CT Oil Tubing Grade Chemical Composition

Grade | C≤ | Si≤ | Mn≤ | P≤ | S≤ | Cr≤ | Ni≤ | Cu≤ | Mo≤ | V≤ | Als≤ | ||

API 5CT H40 | 0.030 | 0.030 | |||||||||||

API 5CT J55 | 0.34-0.39 | 0.20-0.35 | 1.25-1.50 | 0.020 | 0.015 | 0.15 | 0.20 | 0.20 | / | / | 0.020 | ||

API 5CT K55 | 0.34-0.39 | 0.20-0.35 | 1.25-1.50 | 0.020 | 0.015 | 0.15 | 0.20 | 0.20 | / | / | 0.020 | ||

API 5CT N80 | 0.34-0.38 | 0.20-0.35 | 1.45-1.70 | 0.020 | 0.015 | 0.15 | / | / | / | 0.11-0.16 | 0.020 | ||

API 5CT L80 | 0.15-0.22 | 1.00 | 0.25-1.00 | 0.020 | 0.010 | 12.0-14.0 | 0.20 | 0.20 | / | / | 0.020 | ||

API 5CT P110 | 0.26-035 | 0.17-0.37 | 0.40-0.70 | 0.020 | 0.010 | 0.80-1.10 | 0.20 | 0.20 | 0.15-0.25 | 0.08 | 0.020 | ||

API 5CT Oil Tubing Grade Physical Strength

Steel Grade | Yield Strength (Mpa) | Tensile Strength (Mpa) |

API 5CT H40 | 276-552 | 414- 60,000 psi min |

API 5CT J55 | 379-552 | ≥517 |

API 5CT K55 | ≥655 | ≥517 |

API 5CT N80 | 552-758 | ≥689 |

API 5CT L80 | 552-655 | ≥655 |

API 5CT P110 | 758-965 | ≥862 |

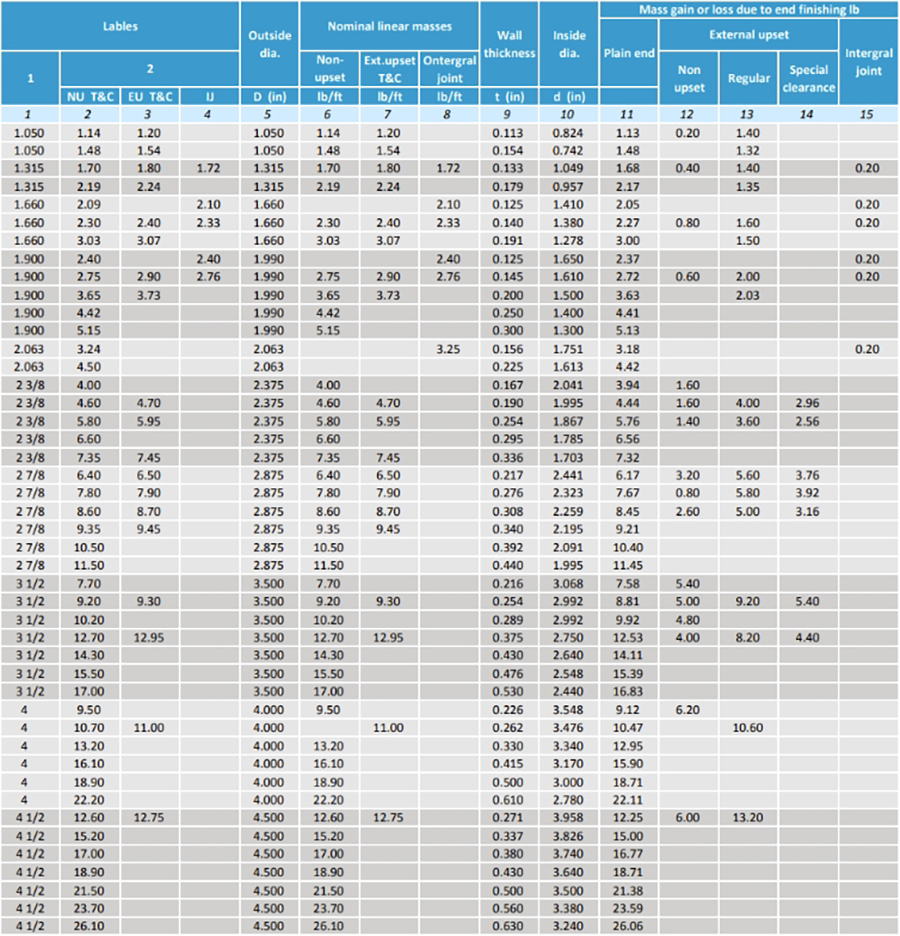

API 5CT Oil Tubing Grade dimensions and weight chart

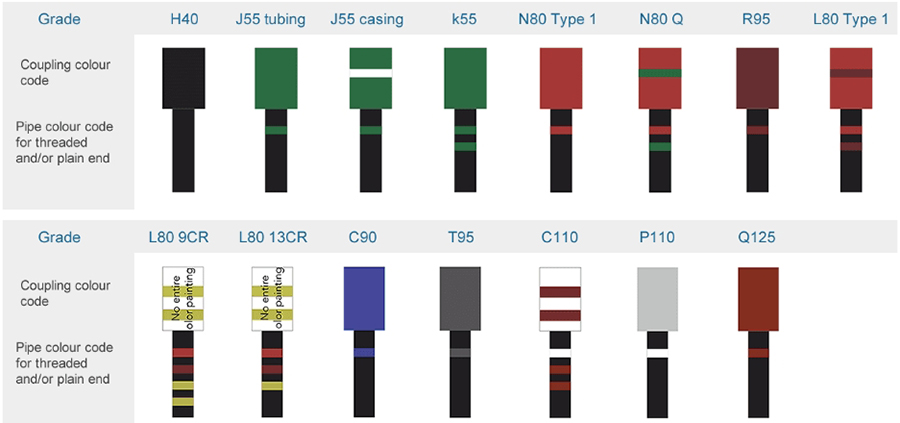

API 5CT Oil Tubing coupling Color