Type

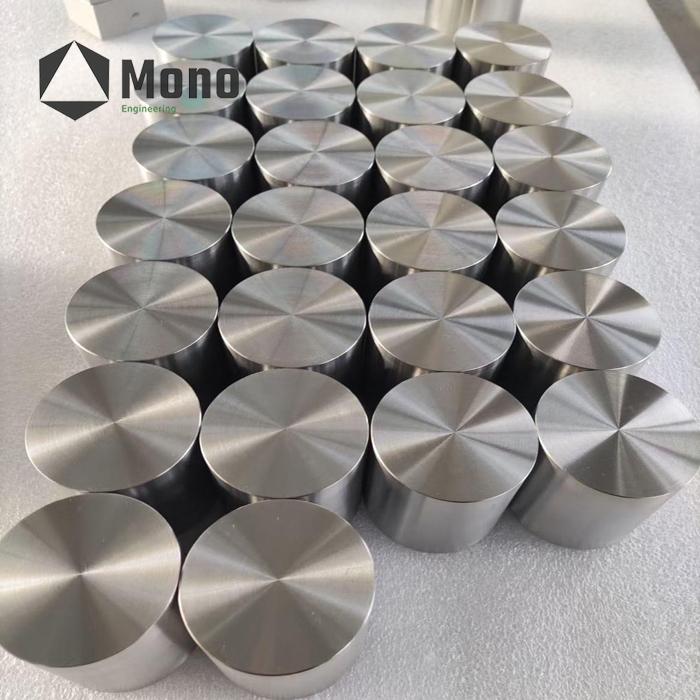

This specification applies to Aerospace using Alpha-beta 6Al-4V ELI, Titanium alloy bars, wires, forgings, flash welding rings and forgings or flash welding ring blanks.The size range is 4.000 inches (101.60 mm) and under in nominal diameter

Application

Mainly used for parts requiring good coal properties, plasticity and solution-820T (-196°C) with good notch toughness.

Chemical components(%)

Composition | C | O | N | H | Fe | Al | V |

Min | \ | \ | \ | \ | \ | 5.50 | 3.50 |

Max | 0.08 | 0.13 | 0.05 | 0.0125 | 0.25 | 6.50 | 4.50 |

Tensile Properties (Minimums)*

Tensile: 120 – 125 ksi Elongation: 8 – 10%

Yield: 110 – 115 ksi Reduction of Area: 15 – 25%

*Tensile property requirements vary based on orientation, section thickness/diameter, and cognizant engineering organization requirements.

Condition

Bar

Hot finishing, diameter reduction with or without subsequent cold processing, annealing and removal of scale.

Wire material

Cold drawn, annealed and oxide scale removed.

Forgings and flash welding rings

Anneal and remove scale.

This flash welding ring is generally not allowed unless specified or permitted in the user's separate drawing. When supplied, ring materials shall be manufactured in accordance with AMS7498

Annealing

Bars, wires, forgings and flash weld rings should be annealed, heated to 1300~1450F (704~788 °C), held at the selected temperature ±25 °C (±14 °C) for not less than 1 hour, and cooled The speed meets the requirements of 3.4. The identification of the furnace and the calibration of the temperature controller and recorder shall be carried out in accordance with the requirements of MIL-H-51200.

MONO Group is one of Titanium and Titanium alloy manufacturer&Supplier&Wholesaler from China,We can supply ASTM /DIN/ISO/GB/AMS stndard high quality Titanium plate,sheet,round bar,wires,tube.pipes,fittings,flange,pls contact us freely for your RFQ to info@monokj.com