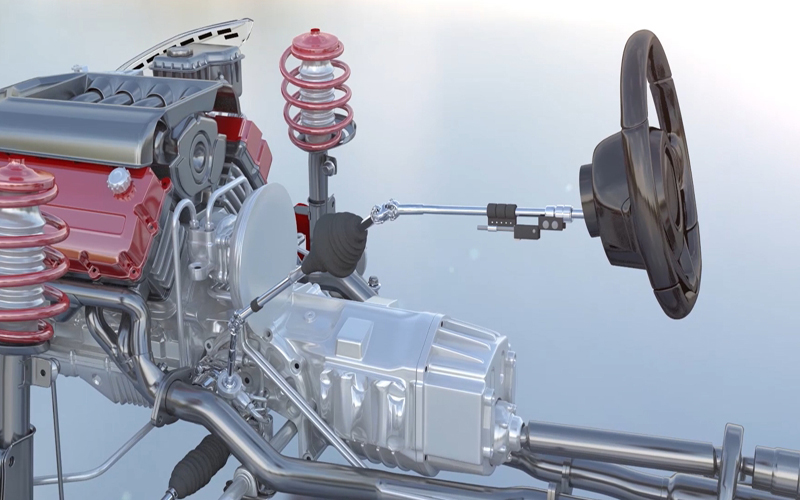

The application of titanium alloy in the automotive field is mainly reflected in the following aspects:

1. Engine parts: Titanium alloy is mainly used to make engine crankshafts, connecting rods, intake and exhaust valves, valve springs, valve reeds, valve baffles and cylinder parts. The purpose of using titanium alloy to prepare engine parts is to reduce weight, increase vehicle speed and save energy.

2. Exhaust system: Titanium alloy exhaust pipes have good high temperature resistance and corrosion resistance, which can improve the emission performance of automobiles and reduce environmental pollution. Titanium alloy tail nozzle/return pipe components are not corroded by chloride salts and sulfur-containing exhaust gases, and are lighter than traditional stainless steel exhaust systems, which improves fuel efficiency, accelerates acceleration, and shortens braking distance.

3. Body and suspension system: Titanium alloy body and suspension system parts can effectively reduce the weight of the car, improve fuel economy and driving performance. The application of titanium alloy parts can reduce engine vibration and noise, increase crankshaft rotation speed, reduce crankshaft stress, obtain higher engine torque, increase the critical speed of engine valve vibration, reduce spring load, reduce valve mechanism wear and reduce fuel consumption.

4. Other applications: Titanium alloys are also used to manufacture automotive fog lamp parts, manual converter noise prevention devices, and gas exhaust control devices with engines as the main mechanism.

Titanium alloys are increasingly widely used in the automotive field due to their high strength, good corrosion resistance, and high heat resistance. From engine parts to exhaust systems, to body and suspension systems, the importance and advantages of titanium alloys are reflected.