In industrial compressed air systems, aluminum pipes (common grades: 6061, 6063) are rapidly becoming the preferred choice over traditional steel pipes due to their comprehensive advantages.

1. Lightweight & Easy Installation

Aluminum pipes are only 1/3 to 1/7 the weight of steel pipes, making handling effortless. The modular design boosts installation efficiency by ~70% and cuts construction time by over 60%.

2. Corrosion Resistance & Maintenance-Free Long Life

A dense oxide layer on aluminum pipes provides superior corrosion resistance, ideal for harsh conditions like high humidity and salt spray. They offer a service life of >20 years with no maintenance.

3. Smooth Interior for Energy Savings

The precision-polished inner wall (e.g., Grade 6061, Ra ≤0.4 μm) reduces pressure loss by nearly 40%. Every 1 bar reduction in pressure loss saves 7%–10% in energy costs.

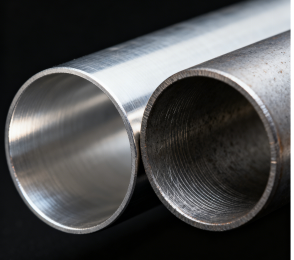

Aluminum(left) vs Steel Pipes(right)

4. Lower Lifecycle Cost & Eco-Friendly

While initial costs are similar, aluminum pipes reduce maintenance costs by ~70%. Aluminum is also 100% recyclable, offering clear economic and environmental benefits over its full lifecycle.

5. Application Comparison

lAluminum Pipes: Ideal for applications requiring lightweight, corrosion-resistant, and energy-efficient solutions, such as compressed air systems, automotive, and food & pharma industries.

lSteel Pipes: Better suited for extreme strength and load-bearing applications, like structural construction and bridges.